About

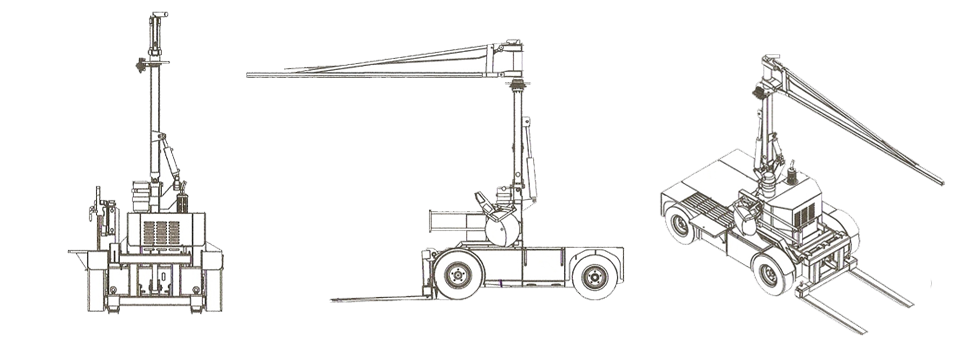

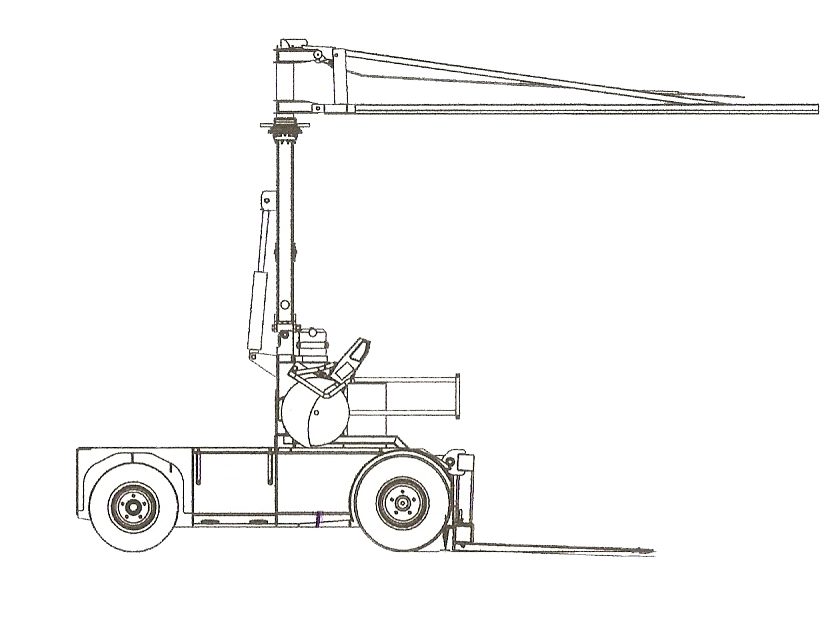

A single machine solution to the installation of kerbs and paving. This compact handling machine combines, fork lift function, guided saw, lift and laying function, radio remote control, an auxiliary hydraulic function, a load carrying deck which double as a saw table/work bench and the option for a power washer. Fork lift function.

KR Annett Material Handling Solutions (KRMAS)

Having been involved in the installation of road side kerbs and pavements for two decades and our family having been involved for three generations, the need for an easier way has not been lost on me. For many years there has been a determined effort by manufactures to mechanise the lift and lay process of kerbing and paving. Indeed EU legislation requires the process to be mechanised. As a result many machines have been created to meet this requirement.

On too many road construction/street works schemes, the mechanisation represents an increase in cost. In many cases multiple machines are required in order to comply or due to the confines of space and time compliance is not even practicable. Drawing from our family experience on road/street construction and on a personal knowledge of mechanical engineering, SWM was created. Created not as a means of compliance but a tool to lift and lay faster and more efficiently, an opportunity taken to combine machines and functions in one compact unit. Compliance with manual handling, noise, and dust suppression/respiratory legislation is subsequent to the design.

The commercial benefits.

Every street works and construction site, every street works and construction contractor is unique but we seek to demonstrate to you how the versatility and agility of SWM can reduce your costs and increase your productivity.

Street works contractors may soon be divided into two groups, those with SWM and those without. Those without will be at a distinct commercial disadvantage.